Wind Turbine Fasteners from Intact360

If it is installed correctly, a wind turbine can function reliably for up to 20 years. After being set up, it is essential that the wind generators remain stable in order to effectively harness the wind’s energy. Wind generators must remain stationary at all times to prevent damage and loss of efficiency.

Hiring a professional construction crew experienced in the use of superior screws and bolts is essential if you want your wind turbines installed securely and without Pollution or Harmful Substances.

Where Are Bolts Used In The Wind Power Tower Turbines?

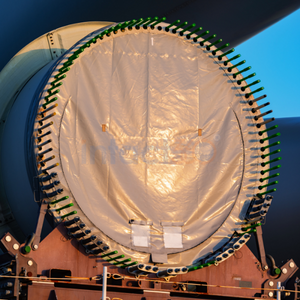

A bolt is a fastener, a tool for mechanically connecting two or more parts. Bolts are commonly used to fasten wind turbine rotors to the shaft. Bolts in today’s wind turbines, therefore, have to be extremely sturdy. They anchor the generator to the tower and link the rotating blades of the turbine. The tower and the earth are both joined by the bolts. Because of their size and weight, wind turbines require a sturdy mounting system. The bolts for many turbines are linked to the tower through a mounting plate.

Turbines for harnessing wind power are intricate equipment that feature many moving parts. Each of these components is necessary for proper operation, but only in tandem can they do their jobs. Bolts in wind turbines are crucial because they are frequently the only point of contact between the towers the turbines are installed on and the ground. Bolts are often called “elbows” in the wind energy sector.

Wind Turbine Fasteners

Numerous fasteners, including bolts, nuts, washers, pins, rivets, pins, screws, studs, and clips, are used to assemble the numerous components of a wind turbine. Bolts, nuts, washers, and other fasteners on turbines may be loose or threaded. You need not be concerned about the fasteners causing harm to your possessions.

Wind Turbine Bolts From Intact360

Bolts are used to connect turbine components such as blades and hubs. Turbine nuts are used to secure the blades to the hubs, whereas turbine pins secure the hubs to the tower. The flanged ends of turbine washers hold the bolts that join the hubs to the tower. A turbine’s hub flanges and bolts are kept together by rivets. Turbo screws secure the wheel flanges to the bolts. The turbine hub flanges have studs that hold the bolts in place. The turbine clips secure the turbine hub flanges to the bolts.

You may discover that adding additional bolts to your wind turbine enhances its stability and dependability. Therefore, it is necessary to ensure that they are of excellent quality and have practical utility.

Before they may be utilized, bolts for wind turbines must conform to specified specifications. Even though the bolts are composed of high-quality steel, they will only reach their maximum performance potential if they are fitted correctly. In wind turbines, numerous different types of bolts are utilized.

Despite the fact that they are all constructed of steel, there are tiny variances between them. By a significant margin, the nut-less self-locking version is the most popular type of bolt. There are wind turbines that use thread inserts to strengthen the bolts’ security. These inserts permit the bolts to be entered from any angle, which is advantageous when working in limited locations.

Wind Turbine Foundation Bolts

The efficiency and lifespan of a wind farm depend on the stability of its turbines, which can only be achieved with a solid base that does not change the natural flow of the wind. It is important to make sure the turbine’s automatic shutters and rotors can withstand the weight of the structure.

A wide variety of fasteners are available for this purpose. When using these anchors, you can safely attach towers to the ground or pier blocks. It’s hard to overestimate the value of their reliable fastening and longevity in the face of corrosion.

What Are Some Standard Bolt Dimensions For Wind Generators?

Bolts for turbines can be purchased prefabricated in a variety of conventional sizes or custom made to fit a specific need. 6.5 inches (165 millimetres), 8 inches (200 millimetres), 10 inches (250 millimetres), 12 inches (300 millimetres), and 16 inches (400 millimetres) are the most typical (400 mm). In addition to the standard imperial sizes of 10mm (3.94in), 12mm (4.72in), 16mm (6.30in), 20mm (7.87in), and 25mm (1.98in), turbine bolts are also produced in metric sizes (0.98 in).

Wind Turbine Nuts From Intact360

A wind turbine’s nuts might be the most important part of the machine. These bolts are used to connect the wind turbine’s blades to the hub, where the shaft meets the generator. The rotor blades of a wind turbine spin a propeller, which moves the machine forward. Given how big and fast the blades are, the tower they will be attached to needs to be very strong.

Tower nuts for wind turbines can be roughly divided into two categories:

Different types of nuts, including compression nuts and Socket nuts. Compression nuts are typically used to fasten the rotor blades to the hub. There are a variety of turbine parts, and their function is to link them all together.

Socket nuts can only be used with certain kinds of fasteners. The socket is fastened in place by forcibly screwing it into the threaded nut. Put it in the socket and tighten the screw to keep it there.

Wind turbine assembly and maintenance bolting and tensioning equipment

Instruments for applying tension on wind turbine blades. The tension of the blades on the shaft can be changed. It takes a team effort to fine-tune the blade pitch for maximum efficiency. Tension tools are useful for both manufacturers and repairmen of wind turbines.

Tension tools are useful for both manufacturers and repairmen of wind turbines. Tension tools are used by wind turbine manufacturers for blade tension adjustment and bolt tightening. The blade will continue to rotate as long as there is wind. The tension instruments are utilised to fasten the blades to the shaft. Blade tension can be kept consistent with the help of spring-loaded mechanical tension equipment like torque wrenches.

The tension on the blade is constantly applied by the spring. When the spring comes into contact with the bolt, it is compressed. With further compression, the blade will experience greater tension. The tension on the bolts can be secured once the torque wrench has been adjusted to the correct setting.

Adjusting the torque wrench to the correct setting for the bolts determines the tension. Once the torque wrench is set to the proper level, the tension will remain unchanged.

Wind turbines are mechanical devices, hence they are subject to wear and tear like any other equipment. Most wear and tear is concentrated on the tension tools, which are used to tighten the bolts connecting the blade to the tower. Bolting and tensioning equipment in wind turbines provide crucial functions. They have to keep the cutting edges safe and in good working order. When bolts and nuts are not tightened to the correct torque, the blade assembly could fail.

Here is a list of the different kinds of tools used for bolting and tightening:

- Automatic Bolt Tightening Tools: With these tools, all bolts can be tightened and fastened automatically, without having to do any work by hand. Automated tightening tools are very important because they remove the chance of human error.

- Tools for tightening bolts by hand: Each bolt needs to be tightened by hand with these tools.

- Bolts and nuts are used to put things together and make them tighter.

- These are inspection tools that are used to check bolts, nuts, and other fasteners.

- Tools for checking and measuring: Bolting elements are checked and measured with these tools.

- Devices for Checking and Measuring Bolts, Nuts, and Other Fasteners: These tools are used to check and measure bolts, nuts, and other fasteners.

- There are bolting and tensioning devices that help fasten bolts, nuts, and other parts to wind turbines.

- Assembly and maintenance of wind turbines is the process of building and taking care of wind turbines.

- Wind turbine service, which is another name for wind turbine maintenance, is a part of wind turbine assembly and maintenance.

- Putting up a wind turbine is part of wind turbine service, as is putting up a wind turbine.

- People who keep wind turbines running